An extract from Kilner Bros. Jubilee, with many thanks to Alan Duffty for his help

50 Years in the Glass Bottle Trade

Messrs. Kilner Brothers Jubilee

Caleb Kilner

The bottles made at Conisbrough are chiefly mineral water, spice, confectionery, wine and spirits, pickle, medicine, and chemists. and druggists bottles of all descriptions.

There is a separate department for grinding marbles orglass balls to be inserted in the patent and internal stoppered bottles. These are first cast in a mould, and then by a quick and ingenious process ground into perfectly spherical form. There are as many as 15 women employed upon this class of work alone.

Here are also large smith’s and machine shops for repairing the blow-pipes and moulds, steam hammers being in use. The smith’s shop is a spacious building containing six fires, steam hammer, lathes, drilling machines etc. All the moulds are fitted up and lettered, all work and repairs being done in connection with the place.

The warehouses are six in number, and have a floorspace of over 6000 squarefeet. One of the warehouses consists of four floors and basement, and another is fitted up with hot water arrangements for washing and drying bottles. There are also two steam cranes for loading goods direct into railway trucks.

The works also include steam cranes at the wharf, mortar mills, steam pumps, fire engine, and large tanks for water. The plant is capable of a weekly output of 300,000 bottles.

In the mould store, we could not but notice the great variety of moulds. More than 3000 moulds are stocked. Adjoining this is the carpenter shop for repairing crates, cases etc.Upstairsa room is full of pots in which the materials for making flint medical bottles is melted.

The firm have here 76 cottages occupied by their work people. We must mention also, in connection with the works here and that Thornhill and the London warehouses, that the latest arrangements are in hand for instantly checking fire.

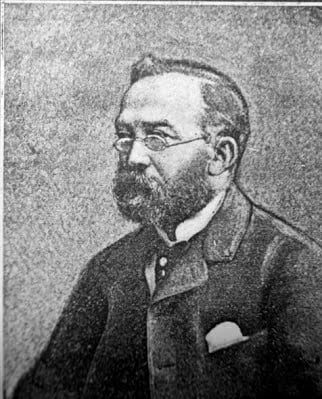

Conisborough Glass bottle Works 1894

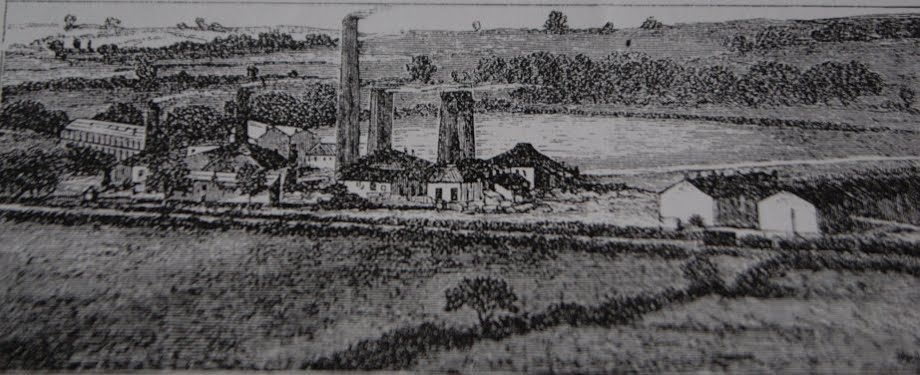

Conisborough Works 1875