Mexborough and Swinton Times March 2, 1888

The Glass Bottle Industry

Its Present Condition and Prospects

Another Move in the Right Direction

I had heard so much of the wonderful method by which it is alleged that thousands of bottles can be-turned out in an incredibly short space of time with the assistance of an ingeniously contrived machine, that notwithstanding the failure which attended the Castleford experiment, I was impressed with the idea that the trade afforded opportunities for improvements similar to these which we see brought into daily use in all our principal manufactories.

The old-fashioned method of glass bottle making has now almost be superseded by Siemens system, and good judges entertain the, most confident hopes that further inventions of quite a practical nature will as time goes on be introduced into the business.

During the latest of the new order of things, heating of boilers by gas instead of, as previously, by common fuel, has been adopted, though only in a limited degree, by the glass bottle manufacturers of Yorkshire

The new process appears to me to be an important step, and will result in a revolution, to a certain extent, of notions that for years and years have governed the trade. The patent has been taken out bt- Edward Brook of Huddersfield, styled “Brook’s patent gas producer,” and one of the first glassworks in the kingdom at which it has been adopted is that of Messrs. Kilner Bros., of Conisborough.

Within the last few weeks the firm have erected one-of these gas producers, and impelled by the importance which in attached to the innovation, and also a desire to see what glassblowing really was, I was induced to pay a visit to the works in question.

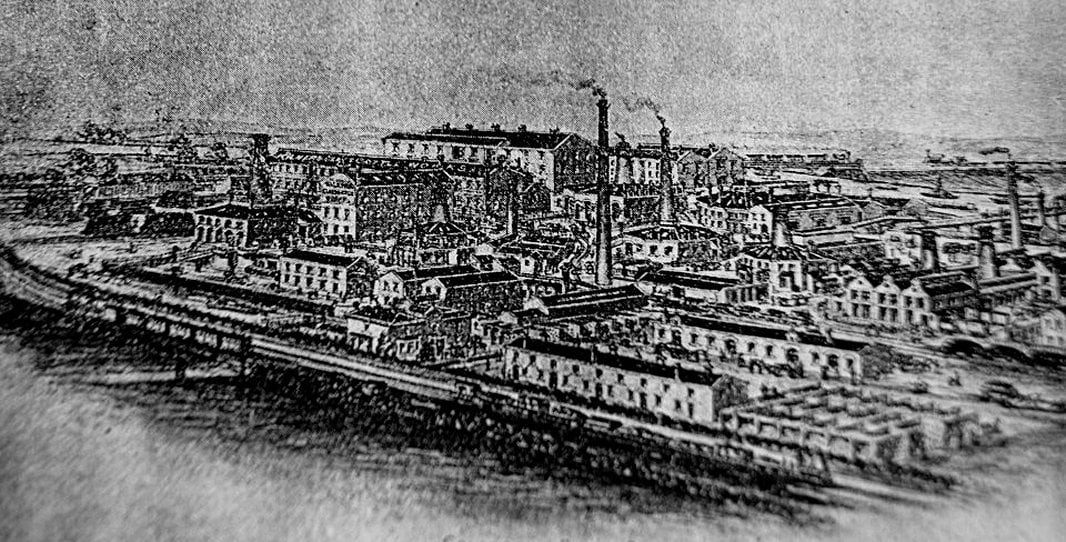

The premises of Messrs. Kilner Bros. though, as far as I know bearing no name, occupy a very conspicuous position on the left-hand side of the M. S. and L. railway between Denaby Main and Conisboro’, and the name of the firm is blazoned forth on one of the -warehouses. The place has grown from a small beginning to considerable as I mentioned, details of which we made it our business to enquire. Like its neighbours—the works if Mr. Barron and Sons and P. Waddington and Sons, at the neighbouring town of Mexborough—Messrs. Kilner Bros. glasshouses are a very important factor in the prosperity of the district and were even one of them to discontinue operations the cessation of work to the hundreds of hands who thus find employment would be severely felt in the district.

When I paid my visit to Conisboro’ I unfortunately selected Saturday,—unfortunately, because during the afternoon, when I arrived, the men had just left work, and I was deprived of the pleasure of witnessing and of having explained to me the whole of the mysterious processes which culminate in the production of the numerous variety of bottles which the works turn out. However I determined that my visit should not be paid for nothing, and, wish true journalistic instinct, contrived to see and hear sufficient, at all events, to find material enough for these columns. I mention this so that practical readers not find fault. It is simply a plain unvarnished tail of what I saw and nothing more.

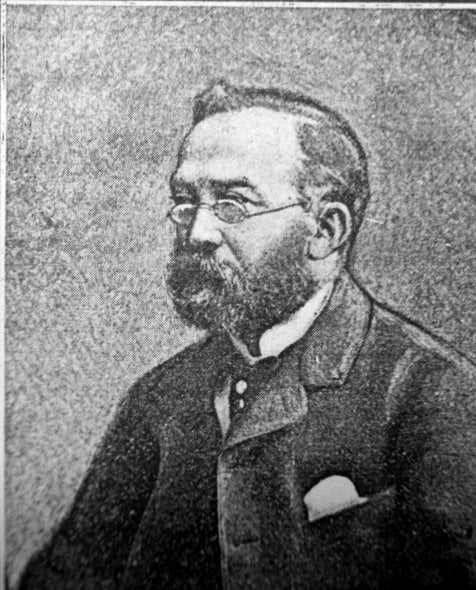

The first face I met with was the genial countenance of Mr. Caleb Miner, partner in the firm, and manager of the Conisboro’ works; and here, I may mention that there a much larger establishment in connection the same firm at Thornhill Lees near Wakefield.

Mr. Kilner haying heard of my mission, kindly volunteered to show me round the place, but not before I had expressed dismay at the task before me, as I had “little or no knowledge of things appertaining to glass bottles, though I certainly had heard glass-blowers a on pay-day haggle about “‘dozens ” and so forth:

We first of all went to the primary object of my visit, the patent gas producer. It had only lately been put up, and, in fact, only been in working order a few days before my inspection. It leaked like a large tank, and was fixed only few feet off the boiler which it supplied.

But before going any farther at must attempt to describe what this gas producing is and what it does. The great objects are the consumption of all smoke, and the saving in fuel. Mr. Kilner said these gas produced were much cheaper than heating his boilers in the first instance by coal ; and in the next place the intolerable nuisance of the chimneys continually pouring forth dense black volumes of smoke was obviated. The coal which feeds this producer is thrown in through an opening at the top, and is distributed evenly over the fire inside. There is a grate at the bottom which this continuously revolved by machinery, the Fire and the’ useless embers are forced out when no further service is required of them.

The gas which is generated, and all the smoke, is parsed along a huge tube into the boiler, and here it succeeds in heating the water to any degree. It appears to be incredible, but by this simple contrivance every particle of smoke is consumed, and in addition to this the system possesses the additional advantage of being considerably cheaper. Of course, the cost of the producer, in the first instance, is an important item, but this, Mr. Kilner who for me, was soon made good by the saving effected.

By a little reflection I was induced to ask my guide if he did not think the days of smoke and grime were numbered, as it appeared to me that if smoke could be done away with in a glass works it could be done away with anywhere, “Yee,” he said, “I think the time will arrive when we shall be able to dispense with smoke altogether in all kinds of manufacture.”

I had heard the theory propounded before, often enough, but this was the first time I had heard it from a practical man, and it set me in a brown study, and I dreamed of the time when the clear cloudless skies and the sweet balmy, air of Sheffield would offer as great an ‘inducement to the tourist as the brilliant glory of the Italian heavens. But it is not the journalists’ province to dream; his lot is a hard and very practical one, end his extravagant fancies are apt to be interfered with by the everyday hum-drum nineteenth ‘century disillusions which his duties reveal. So I marked back again, and asked if many other firms had adopted this delightful principle of warming up, and was informed that so far as the glass bottle trade was concerned the patent had by no means been extensively adopted, and that, in fact, Messrs. Kilner and Bros. were the only firm in the district who had. ,

Then I thought I should .like to see something else, and asked Mr. Kilner if trade warranted the considerable increase be had recently made to his warehousing—I alluded, of course, to the commodious building which is yet unfinished and can be seen from the railway. This artfully contrived question induced our conversation to drift into a more personal channel, which I had been striving to attain for some time.

My own common-sense ought to have told me that as a tale, men did not build large buildings unless they had an idea that they would be used, but I got a much more considerate reply than I deserved. Mr. Kilner, for answer, took me round to the packing warehouse, where I saw a number of girls busily engaged in arranging the bottles, carefully packed in straw, in huge crates, preparatory to their despatch to London. The siding from the railway came up flows to this warehouse, and two or three waggons already filled with goods were being removed to the main line by horses.

I asked where they were going, and Mr Kilner said “to London.” He added that the trucks were loided in that yard and taken straight away into their warehouse in London, from where the goods were distributed to their numerous customers.

I expressed a desire to know how long ‘the works had been going, and was told that they were established in 1884; and that though, at first, only one house with four ” holes” comprised the venture, constant additions had been made until the present dimensions were assumed. There were ‘now 57 ” holes,” and, as I afterwards gathered, these “holes “were capable of turning out an enormous number of bottles.

We then went into the smiths’ shop, which is an extensive building fitted up with all the latest planeing machines, steam hammer, lathe, at other mechanical constructions of the newest description: This place gives access to a small lettering room, and here I was shown the process by which the names of the firms which are moulded on the bottles are engraved. The method of engraving is too commonly known to need dwelling on, but Mr. Kilner told me that that week alone 438 letters had been engraved, and I was shown half-dozen moulds just finished awaiting the glass blowers.

I had beard so much about foreign competition and the way in which English manufacturers were being driven out of their own markets that I thought I would endeavour to find out whether the glass bottle trade had suffered in this respect; so I asked Mr. Kilner how he found business, and did he not experience the strong competition in his particular branch that had made itself so strongly felt in other directions.

After a moment’s consideration he replied, “There is no doubt that we are severely handicapped, and we find that the foreigner can sell the same bottles quite as good as ours at the same price and very often less than we can in London.” Indeed,” be added,” we (that is, the trade) often get bottles from the foreigner in London because we can buy them for our customers cheaper than we can make them.”

I thought to myself that if the foreigner could sell bottles in London cheaper than our manufacturers can offer them, and of quite as good quality, how was it that they did not control the whole of the market, and I ventured to put this question to Mr. Kilner. I thought it would be a poser, as I could not conceive a higher price than that of the current market quotation being be paid. Mr. Kilner, however, said that their continental friends did not compete in every class of bottles, and although admitting that the time might come when they would, said the glass trade had been a growing one, and that in some respects the English manufacturers were still able to hold their own, doubtless because of their reputation. In some descriptions of bottles it took the manufacturers all their time to supply the demand, and while that demand remained there was little likelihood of England being shut out from the markets.

Having obtained a half-admission of the danger which is threatened us in the not very distant future I propounded to Mr. Kilner a question which is often used in argument by Fair Traders, although I apologised to Mr. Kilner tor introducing anything into our conversation that might savour of politics. But I told him that the matter had aroused great interest, not only in his particular trade, but also in many others which had felt the pinch of foreign competition, so, as gently as possible I said ” Don’t you think if an import duty were placed on glass bottles from the Continent it would give you the control of the whole of the market in England, and result in a great revival of trade which would not only benefit the manufacturer but also the English working man?”

Mr. Kilner smiled at my ingenuity, and I suspected that I had ventured beyond the domain of legitimate questioning, so I was agreeably surprised when he answered, “It would be bound to make our trade in England better, but then we want to look at it on a broad scale, not from a selfish point of view. If it is good for us, it may not be good for the country.”

Of course I was bound to be satisfied with this, but said, “Well, if you don’t see, any remedy in the imposition of import duties what you think the English manufacturers ought to do? Is there anything they can do?” And” (without waiting for my other questions to be answered) “How do you account for the foreigners being able to undersell us ?”

” Well,” Mr. Kilner replied, ” In the first place their works are situated for the most part either on the seaboards or the principal rivers, so you will see that the craft can get up to the wharves, and, after being loaded can ship their consignments on the wharves in London. There is none, or very little, railway carriage like we have in England. Why it costs us more to send a consignment of bottles from Conisboro’ to our warehouse fifths Metropolis than it does from Germany to London. That is one reason, and one which I cannot see we can very well avoid. Then again, the men work for much less money in Germany than they do in England.” “But,” added Mr. Kilner, “I am decidedly opposed to the lowering of our men’s wages to meet that state of things.”

“Then,” said I, “What on earth can you do?” for I confess I was getting greatly interested in the future prospects of the glass bottle trade, and intended, if I possibly could, to get to the bottom of the puzzle.

“The only remedy that occurs to me is for us to go in for improving the Waterways we have and to make new ones. You “know I am a strong advocate of the canal from Goole to Sheffield, with the idea not only of competing with the railway companies, but also of joining, in time to come, with the Manchester Ship Canal, and opening up districts which, fur practical purposes, are inaccessible to railways. Of course it would be impossible for the glass bottle manufacturers to effect this single handed; it would have to be” by the combination of manufacturers of all kinds, and then the opposition from the railway companies would be powerfully exorcised.”

“Then it is an established fact that railways cannot compete with waterways for the carriage of merchandise?”

“Yes, for heavy goods; although (added Mr. Kilner in reply to a suggestion from me) ” we, that is, speaking for ourselves, have nothing much to complain of with respect to the railway rates at Conisboro’.”

“Won’t technical education help you?” I said, as a remembrance of Mr. Gosohen’s rectorial address flashed across my mind ; ” it appears to be a sort of universal panacea for languishing Industries.” “Could you compete with the Germany if you were Al technically educated; workmen, masters, and all?”‘

For the second time Mr. Kilner smiled. “I don’t think it is required to be technically educated to be a glassblower”—(and I could not help laughing, myself, at the idea of a technically educated glassblower)—” but men cannot be too well educated for the positions of masters and managers. But after all the practical man is better than the technically educated one in our trade, and I don’t think that, so far as glass bottle blowing is concerned, technical education will ever have anything to do with the depression or advancement of business.”

“But,” I observed, “If the carriage of goods to London is such an important factor in the prosperity of your trade, why don’t people establish works near to or in London? I know that fuel and the material, the sand and chalk, cannot be obtained in London, but it struck me that the carriage of goods to London would outweigh the cost of conveying coal and the other minerals you need were you to establish a manufactory somewhere near the Metropolis.”

Mr. Kilner said that here I had been misinformed, and told me that it was considered far better to put down works in a coal district, although, he admitted, there was a decided movement in favour of settling down on a sea board it possible.

Kilner Bros Glass Works in 1894

I then enquired if Mr. Miner could ascertain the number of bottles he turned out in a year, and we went away to the offices for that purpose. I was surprised to learn that the total was 800,000 dozens, or 9,600,000 bottles. On the premises there are employed 890 hands, and to give some idea of the immense warehouse accommodation, the buildings, which are eight in number, cover an area of 19,606 square yards.

I was sorry that another engagement precluded a longer stay, as I had a desire to know other interesting matters connected with the glass-bottle industry, but what I did learn I have ventured to reproduce, and though not professing to be by any means complete, I hope it may prove of interest to you readers.